CONTACT US

The durability and aging behavior of epoxy adhesive bonds are critical factors to consider in their practical applications. Over time, various environmental and mechanical factors can impact the performance of adhesive joints, leading to changes in their mechanical properties and interfacial interactions. Understanding the durability and aging behavior of epoxy adhesive bonds is essential for ensuring long-term performance and reliability. Here are a few key aspects to consider:

1. Environmental factors: Exposure to moisture, temperature variations, UV radiation, chemicals, and other environmental factors can significantly affect the durability of epoxy adhesive bonds. Moisture absorption, for example, can lead to swelling, plasticization, and loss of adhesion. Temperature cycling can cause thermal stresses and subsequent delamination. UV radiation can lead to degradation and discoloration. It is important to assess how these environmental factors impact the bond's strength, stiffness, and overall performance.

2. Aging mechanisms: Epoxy adhesive bonds can undergo various aging mechanisms over time. This includes physical aging, in which the material relaxes and changes its properties spontaneously, resulting in changes in mechanical behavior. Chemical degradation may occur due to exposure to environmental factors, leading to bond strength reduction and interfacial degradation. Understanding these aging mechanisms is crucial for predicting the long-term behavior and degradation patterns of epoxy adhesive bonds.

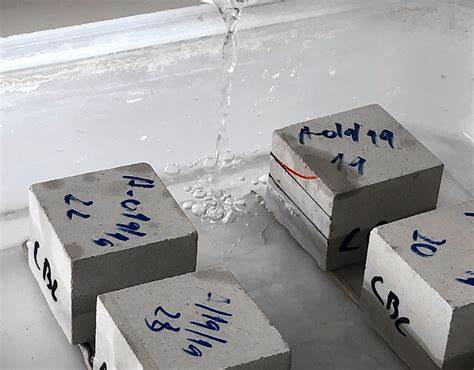

3. Accelerated aging tests: Accelerated aging tests can be conducted to mimic long-term exposure of epoxy adhesive bonds to environmental conditions in a shorter time frame. This allows researchers and engineers to assess how different combinations of environmental factors impact the durability and aging behavior of the bonds. Accelerated aging tests can involve exposure to temperature and humidity cycles, UV radiation, chemical exposure, mechanical loading, and other relevant parameters.

4. Non-destructive evaluation (NDE) techniques: NDE techniques, such as ultrasonic testing, acoustic emission, thermography, and visual inspection, can be employed to monitor and detect any degradation or damage in epoxy adhesive bonds without causing harm to the joint. These techniques can provide insights into changes in bond integrity and interfacial properties over time, allowing for timely intervention and maintenance.

5. Modeling and prediction: Computational modeling and simulation techniques can be employed to predict the long-term performance and aging behavior of epoxy adhesive bonds. By incorporating data from accelerated aging tests and understanding the underlying mechanisms, models can be developed to estimate the remaining service life of adhesive joints under various operating conditions.

By studying the durability and aging behavior of epoxy adhesive bonds, researchers and engineers can develop strategies to enhance bond longevity, improve the resistance to environmental factors, and ensure the reliable performance of adhesive joints over their intended lifespan.

The durability and aging behavior of epoxy adhesive bonds are influenced by various mechanisms. These mechanisms can include physical, chemical, and mechanical processes that occur over time. Here are some key mechanisms:

1. Physical aging: Physical aging is a time-dependent process in which the amorphous epoxy adhesive material undergoes relaxation and changes its properties. During physical aging, molecular rearrangements occur within the adhesive, resulting in changes in its mechanical behavior. This can include an increase in stiffness, reduction in ductility, and decrease in adhesion strength. Physical aging is influenced by factors such as temperature, time, and stress levels.

2. Chemical degradation: Chemical degradation can occur due to exposure to environmental factors such as moisture, chemicals, and UV radiation. Moisture absorption can lead to hydrolysis of the epoxy adhesive, resulting in a reduction in bond strength and interfacial degradation. Chemical exposure can cause degradation of the adhesive matrix, leading to changes in mechanical properties and loss of adhesion. UV radiation can induce photochemical degradation, resulting in discoloration, crosslinking, and reduced bond strength.

3. Interfacial interactions: The long-term durability of epoxy adhesive bonds can be influenced by interactions at the bond interface. This includes chemical reactions between the adhesive and the adherend, such as the formation of chemical bonds or diffusion of species across the interface. Interfacial interactions can affect bond strength, adhesion, and resistance to environmental factors. Factors such as surface preparation, cleanliness, and the presence of contaminants can influence interfacial interactions.

4. Mechanical degradation: Epoxy adhesive bonds can experience mechanical degradation over time due to cyclic loading, stress relaxation, and fatigue. Repeated stress cycles can cause microcracks, delamination, or fracture within the adhesive layer. Stress relaxation and fatigue can lead to a decrease in bond strength and stiffness. Mechanical degradation is influenced by factors such as applied stress levels, frequency of loading, and cyclic loading conditions.

Understanding these mechanisms is crucial for predicting the aging behavior and durability of epoxy adhesive bonds. By studying the physical, chemical, and mechanical processes that occur over time, researchers and engineers can develop strategies to mitigate degradation, improve bond performance, and ensure the long-term reliability of adhesive joints.

Epoxy adhesives can endure aging impacts due to their inherent properties and the use of strategies to enhance their durability. Here are some ways epoxy adhesives can withstand aging impacts:

1. Material selection: Epoxy adhesives with high chemical resistance and thermal stability are often chosen to ensure durability and resistance to aging impacts. The selection of materials with appropriate properties, such as high crosslinking density and low moisture absorption, can help mitigate aging effects.

2. Additives and modifiers: Additives and modifiers can be incorporated into epoxy formulations to improve aging resistance. For example, antioxidants can be added to combat oxidation processes, while UV stabilizers help protect against UV degradation. Fillers or reinforcements can also be included to enhance strength and reduce the impact of aging.

3. Proper curing: Epoxy adhesives must be properly cured to maximize their strength and durability. Following the recommended curing temperature and time ensures the adhesive achieves its full potential for resistance to aging effects.

4. Surface preparation: Adequate surface preparation is essential for optimal bond strength and resistance to aging. Proper cleaning and treatment of the adherend surface remove contaminants and promote better adhesion, reducing the likelihood of interfacial degradation and aging impacts.

5. Controlled environmental conditions: Exposure to extreme temperatures, humidity, chemicals, and UV radiation can accelerate aging processes. Maintaining controlled environmental conditions can help minimize the impact of these factors on epoxy adhesive bonds. This can be achieved through protective coatings, temperature/humidity control, or encapsulation.

6. Application-specific designs: Understanding the specific use and aging environment of the epoxy adhesive is crucial in designing for durability. Factors such as anticipated loads, operating temperatures, and exposure to chemicals or UV radiation should be considered when selecting the appropriate epoxy adhesive and designing the bond joint.

By implementing these strategies, epoxy adhesives can better withstand aging impacts, maintain their mechanical properties, and ensure long-term bond performance. Regular inspection, monitoring, and maintenance are also important to detect any signs of aging degradation and address them before they compromise the integrity of the adhesive bond.