CONTACT US

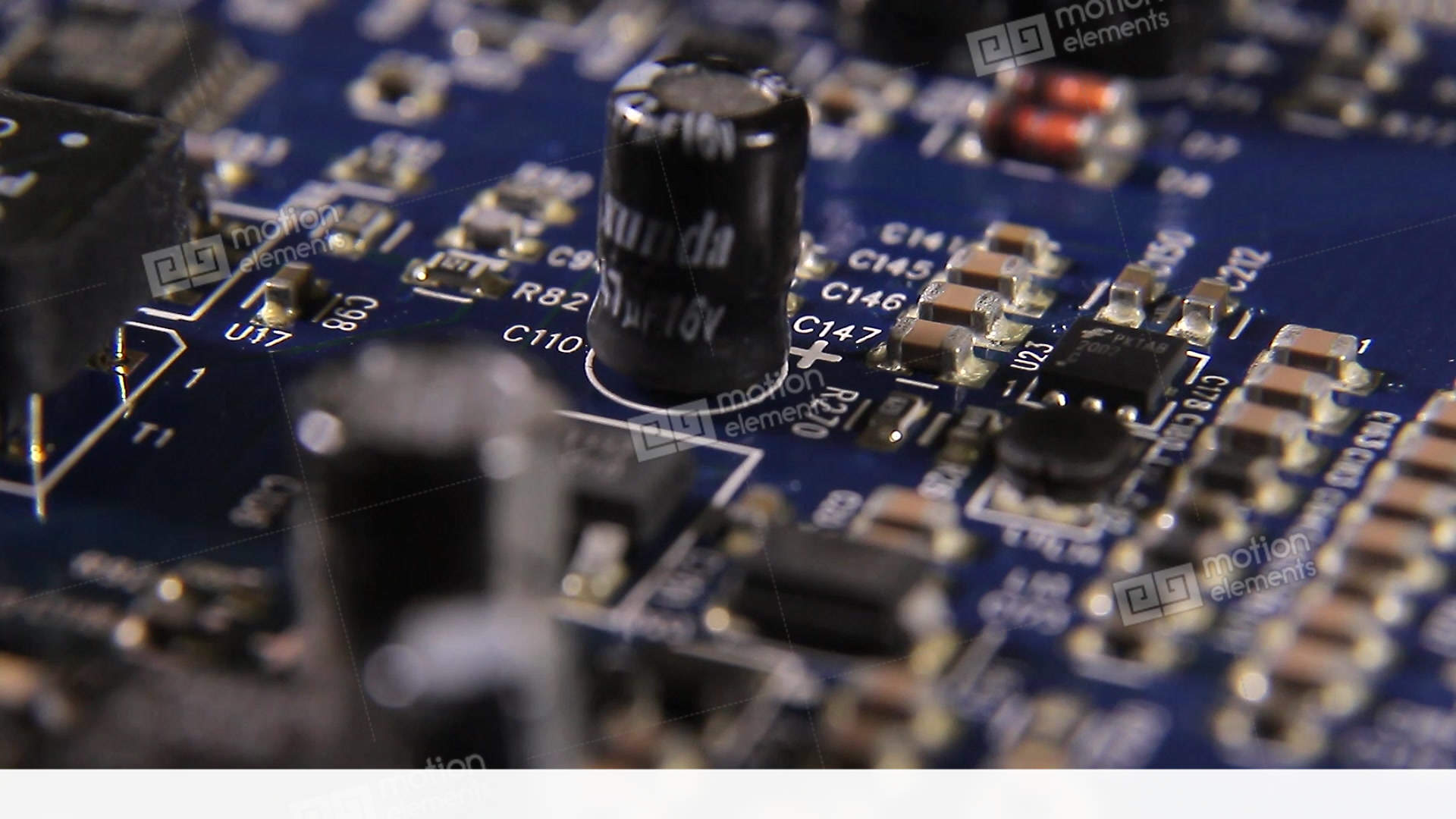

Self-healing epoxy adhesives can also be beneficial in electronic component assembly. Here are some points to consider:

1. Improved reliability: Electronic components can experience stress, vibration, or thermal cycling during operation, leading to cracks or failures in adhesive bonds. Self-healing epoxy adhesives can autonomously repair these cracks, reducing the risk of failure and improving the overall reliability of electronic assemblies.

2. Enhanced lifespan: The self-healing properties of these adhesives can extend the lifespan of electronic components by repairing any damage that may occur over time. This can help prevent performance degradation or premature failure of the assembly.

3. Protection against environmental factors: Electronic components are often exposed to harsh environmental conditions, such as moisture, temperature variations, or chemical exposure. Self-healing epoxy adhesives can provide additional protection by sealing gaps or cracks and preventing the ingress of contaminants.

4. Time and cost savings: By automatically repairing cracks or damage, self-healing epoxy adhesives can reduce the need for manual repairs or replacements. This can save time, labor costs, and minimize the need for frequent maintenance.

5. Design considerations: It is important to consider the specific requirements of the electronic components and assemblies when using self-healing epoxy adhesives. Factors such as temperature tolerance, compatibility with other materials, and electrical conductivity should be taken into account during the selection and design process.

6. Validation and testing: Before implementing self-healing epoxy adhesives in electronic component assembly, thorough validation and testing are crucial. This includes evaluating the adhesive's mechanical properties, healing efficiency, electrical conductivity, and long-term performance in relevant operating conditions.

Self-healing epoxy adhesives offer promising advantages for electronic component assembly by improving reliability, extending the lifespan of assemblies, protecting against environmental factors, and potentially reducing maintenance costs. However, it is important to carefully assess the specific application requirements and conduct proper testing to ensure successful implementation.