CONTACT US

1. Aerospace Industry: A case study highlighting the use of self-healing epoxy adhesives in aircraft manufacturing, where the adhesive can automatically repair small damages, increasing the structural integrity and durability of components.

2. Automotive Industry: A case study demonstrating the effectiveness of self-healing epoxy adhesives in automotive assembly, where the adhesive can heal minor scratches and cracks, reducing the need for costly repairs and improving the overall aesthetics of the vehicle.

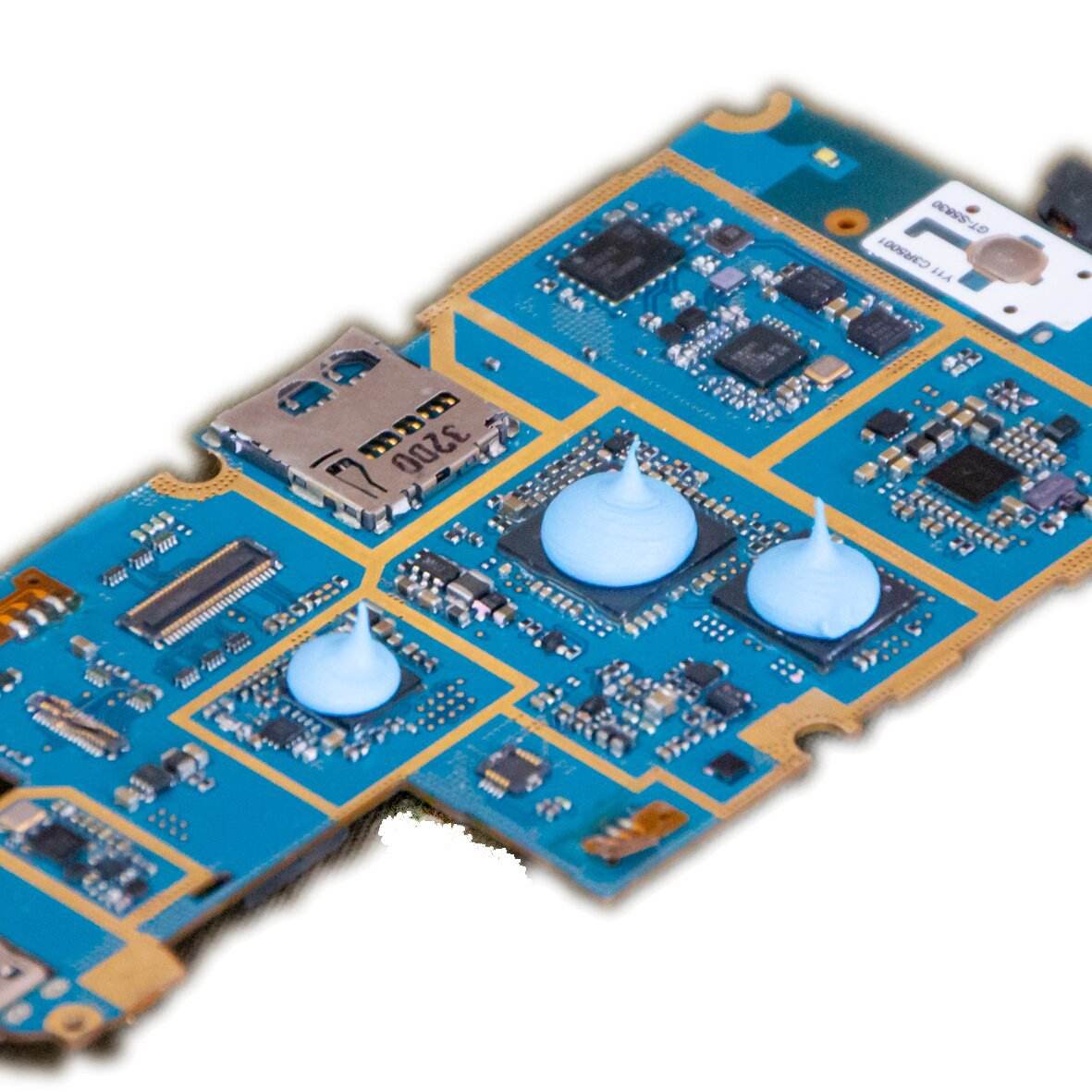

3. Electronics Industry: A case study showcasing the application of self-healing epoxy adhesives in electronic component assembly, where the adhesive can repair small electrical faults or insulation breakdowns, increasing the reliability and lifespan of electronic devices.

4. Construction Industry: A case study illustrating the use of self-healing epoxy adhesives in structural bonding applications, such as concrete repair or reinforcement, where the adhesive can self-repair microcracks, enhancing the structural integrity and longevity of buildings or infrastructure.

5. Marine Industry: A case study demonstrating the use of self-healing epoxy adhesives in underwater bonding applications, such as shipbuilding or offshore structures, where the adhesive can automatically heal damages caused by harsh underwater environments, minimizing maintenance and repair costs.

6. Manufacturing Industry: A case study highlighting the implementation of self-healing epoxy adhesives in various manufacturing processes, such as bonding metal, plastic, or composite materials, providing a more reliable and long-lasting adhesion solution.

7. Medical Industry: A case study showcasing the use of self-healing epoxy adhesives in biomedical applications, where the adhesive can heal microcracks or damages in medical devices or implants, ensuring their functionality and patient safety.

8. Renewable Energy Industry: A case study demonstrating the utilization of self-healing epoxy adhesives in wind turbine blade manufacturing, where the adhesive can repair damages caused by high wind loads or environmental factors, optimizing the efficiency and lifespan of the blades.

9. Packaging Industry: A case study illustrating the application of self-healing epoxy adhesives in packaging materials, where the adhesive can repair minor damages during transportation or handling, preserving the integrity and appearance of packaged goods.

10. Sports Equipment Industry: A case study showcasing the use of self-healing epoxy adhesives in the manufacturing of sports equipment, such as ski or snowboard construction, where the adhesive can heal small dings or delaminations, improving the performance and durability of the equipment.

One application example of self-healing epoxy adhesives is in the automotive industry. In automotive manufacturing, epoxy adhesives are used for bonding various components such as body panels, interior trim, and structural reinforcements.

However, vehicles can be subjected to impacts, vibrations, and extreme temperatures that can cause cracks or damages in these bonded components. Traditional epoxy adhesives would require manual repairs or replacements to fix these damages, which can be costly and time-consuming.

Self-healing epoxy adhesives offer a solution in this scenario. These adhesives contain microcapsules filled with a healing agent that is released when the adhesive is damaged. For example, if a crack occurs in a bonded component, the healing agent would flow into the damaged area, react with a catalyst, and bond with the surrounding adhesive, effectively repairing the crack.

Using self-healing epoxy adhesives in automotive manufacturing can improve the durability and longevity of bonded components. The self-healing properties allow for autonomous repairs of small damages, preventing further deterioration and potential failure. This can result in cost savings for manufacturers by reducing the need for manual repairs or component replacements. Additionally, it can enhance the overall quality and safety of vehicles by maintaining the structural integrity of bonded components.

Aother example of self-healing epoxy adhesive is in the aerospace industry. Aircraft structures, such as wings and fuselages, are often made from composite materials that are bonded together using epoxy adhesives. These adhesives need to have excellent strength and durability to withstand the extreme conditions experienced by aircraft.

However, during the lifespan of an aircraft, composite structures can develop small cracks or damages due to various factors such as impact, fatigue, or exposure to environmental conditions. Traditional epoxy adhesives would require manual repairs or replacements to fix these damages, which can be time-consuming and costly.

Self-healing epoxy adhesives offer a solution to this problem. These adhesives contain microcapsules filled with a healing agent that is released when the adhesive is damaged, such as when a crack occurs. The healing agent flows into the damaged area, reacts with a catalyst, and bonds with the surrounding adhesive, effectively repairing the crack.

By using self-healing epoxy adhesives in aircraft construction and repairs, the need for frequent manual repairs or component replacements can be significantly reduced. This not only saves time and costs but also improves the overall safety and reliability of the aircraft. The self-healing properties of the adhesive ensure that small damages are autonomously repaired, extending the lifespan of the aircraft structures and reducing the risk of catastrophic failures.